April 25, 2014 — 3D Systems announced that its Medical Modeling Virtual Surgical Planning (VSP) technology — the combination of its production grade 3-D printing and personalized surgery tools — has enabled surgeons to conduct complex surgical procedures on newborn and infant patients with more confidence in safety and success.

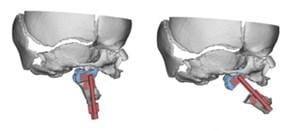

VSP allows surgeons to capture a digital model of the patient directly from an magnetic resonance imaging (MRI) or computed tomography (CT) scan and work with 3DS' Medical Modeling experts to create a detailed surgical plan and then 3-D print physical models and custom surgical guides from 3DS' biocompatible stereolithography (SLA) materials. By accessing 3DS' entire personalized digital thread from perceptual devices like its TouchX haptic, VSP software tools and the guidance of its expert team of biomedical engineers, surgeons can virtually plan and physically practice critical steps of an operation before a patient ever sets foot in the operating room.

In a representative case, experts from 3DS' personalized surgery team used VSP technology to assist Oren Tepper, M.D., attending surgeon, Division of Plastic and Reconstructive Surgery, Montefiore Medical Center, New York, in planning and conducting groundbreaking surgery on a young girl, Jayla Vargas. Jayla was born with an undersized jaw that inhibited her breathing. Traditionally, in such cases, surgeons have been unable to perform the series of surgeries required to reshape an child's jaw due to the pain and risks associated while the patient is very young. However, utilizing VSP technology Tepper successfully corrected Jayla's jaw much earlier than is typical, at one month old as opposed to 6 years old, and spared her additional years of living with a tracheostomy, a surgically created opening in the windpipe to allow proper breathing.

"VSP has not only helped make surgical procedures more precise, but offers the potential to change the scope of what is surgically possible," said Tepper. "In the case of lower jaw lengthening procedures for children, the surgeon can plan the operation on the computer first, and identify any problems before getting to the operating room."

For more information www.3DSystems.com

References

October 21, 2024

October 21, 2024