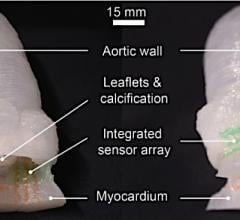

October 30, 2017 — Entering their pre-market phase of development, Materialise is working with select U.S. and EU hospital partners to validate the importance of accurate 3-D modeling to help physicians plan complex transcatheter mitral valve replacement and repair (TMVR/r) procedures.

Mitral regurgitation affects more than 4 million Americans — nearly one in 10 people aged 75 or older. Currently the primary option for the disease is open-heart surgery, which holds extremely high risks for patients in this age group and can prevent treatment in many cases. Non-invasive methods are entering the market to address this need and physicians are recognizing the importance of pre-surgical planning for this complex disease.

The pre-market phase of Materialise’s efforts will assess the importance of accurate 3-D modeling for robust, repeatable patient planning. Materialise has partnered with Henry Ford Health System to bring Henry Ford’s validated, patented, mitral planning workflow, developed in Materialise’s Mimics Innovation Suite to a broader TMVR market.

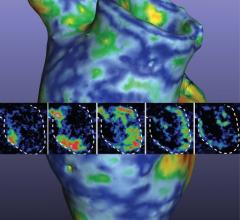

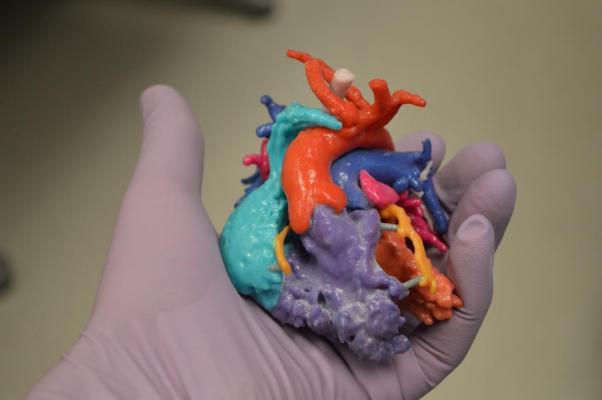

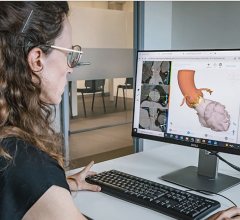

Materialise software enables customized workflows through scripting capabilities to streamline processes. Organizations participating in the Mitral Valve Planning research program will leverage Henry Ford’s validated workflow in Materialise’s Mimics Innovation Suite software where virtual 3-D anatomical models are the basis for assessing left ventricular outflow tract obstructions (LVOTO) and other elements for planning complex mitral valve procedures.

“The mitral valve anatomy is much more complex than other areas of the heart that transcatheter devices currently treat,” said Dee Dee Wang, M.D., director of structural heart imaging at Henry Ford Hospital, and medical director, 3-D printing, Henry Ford Innovation Institute. “The ability to bring advanced 3-D computer-aided design (CAD) technology and software into the transcatheter mitral space has been a real game changer. This 3-D visualization of patient specific anatomy can help cardiologists and surgeons gauge each patient’s mitral annular dimensions to better understand how a device will fit in the patient’s heart and the nature of the obstruction of the left ventricular outflow tract (LVOT) for successful TMVR device implants in highly diseased hearts. This, along with proper imaging and skilled staff, brings periprocedural planning and patient-centered outcomes to a whole new level.”

For more information: www.materialise.com

Related 3-D Printing Content

The Use of 3-D Printing in Cardiology

VIDEO: Use of 3-D Printing to Guide Structural Heart Interventions

October 21, 2024

October 21, 2024